- e-Procurement Preparation

- e-Procurement Basics

- Advanced e-Procurement

- e-Procurement Indicators

- Incorporating e-Procurement into Public Financial Management (PFM) reforms

Target audience

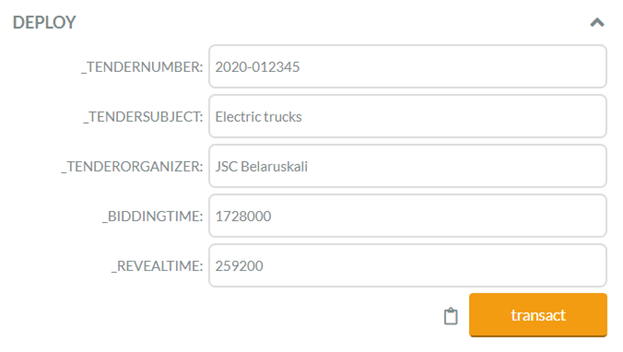

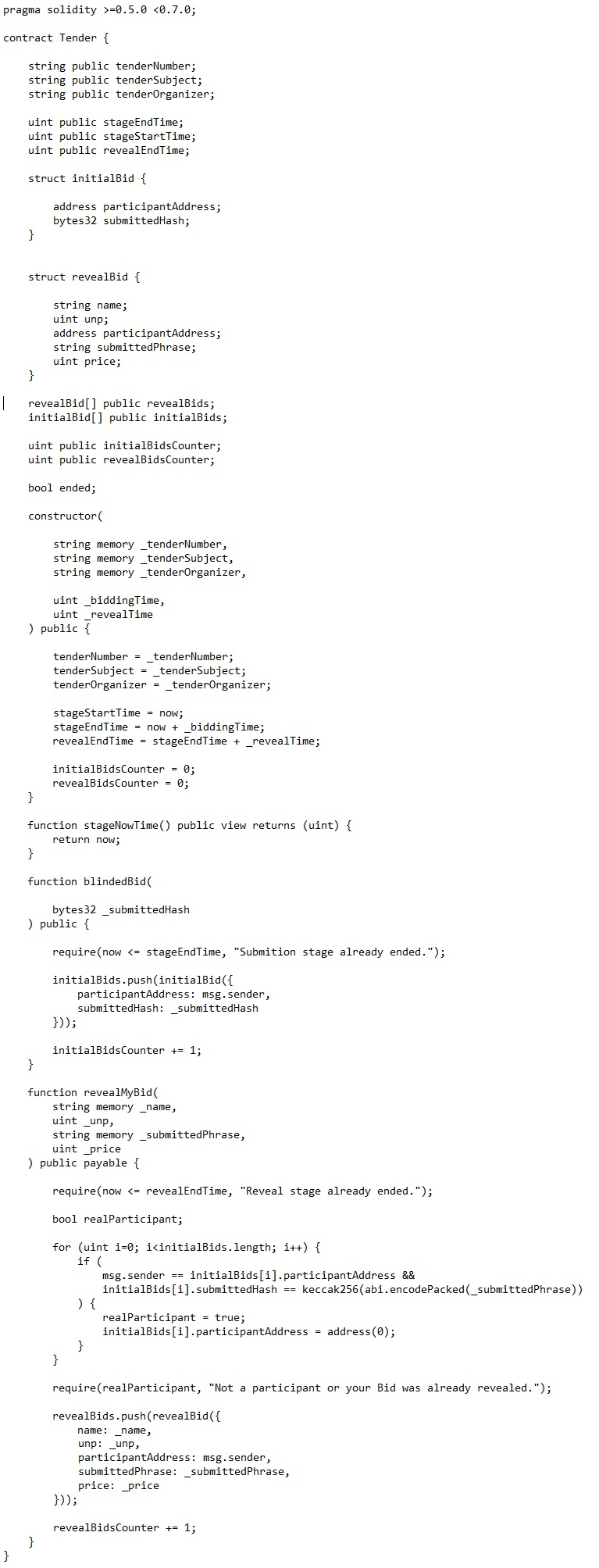

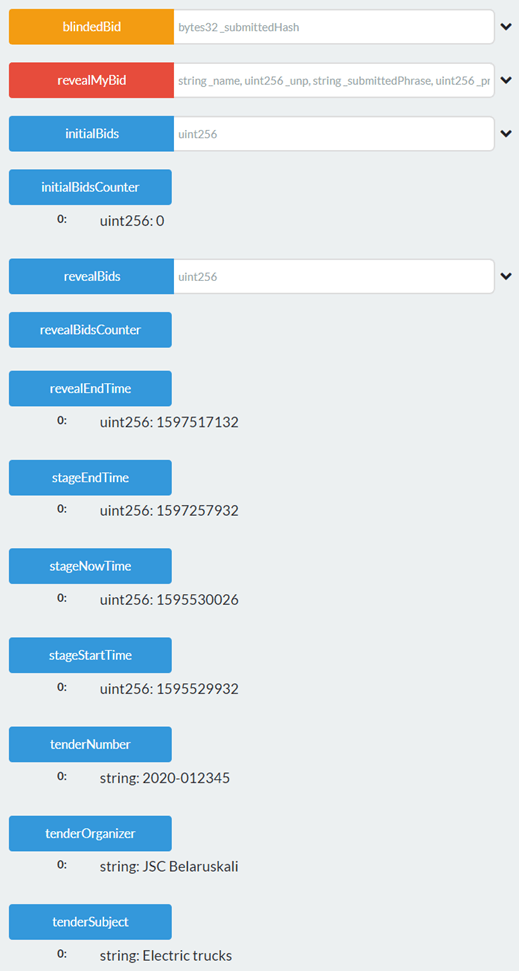

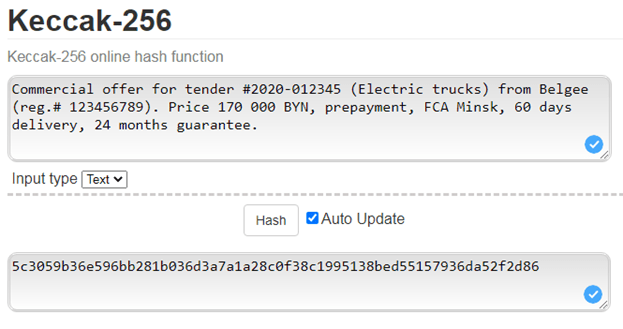

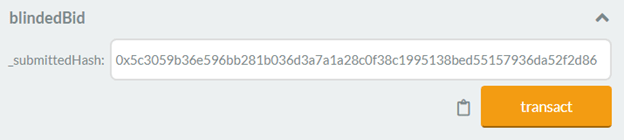

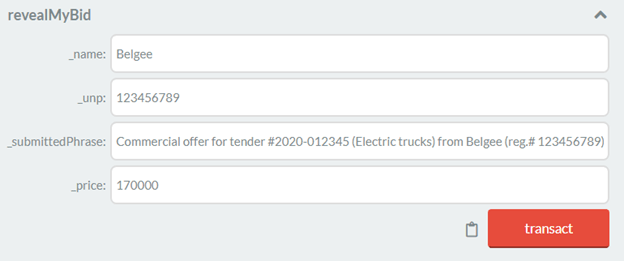

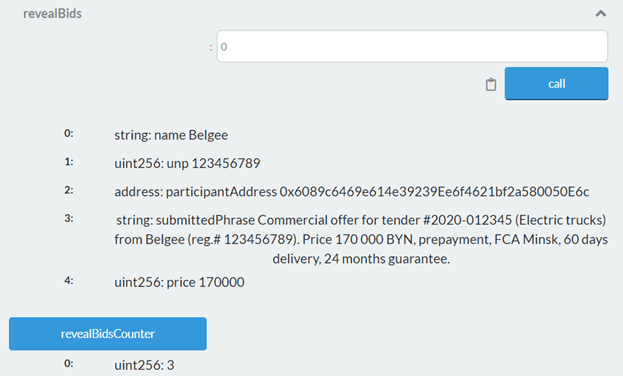

Project: Submitting Initial Commercial Offers

Project: Submitting Initial Commercial Offers

16.10.2020

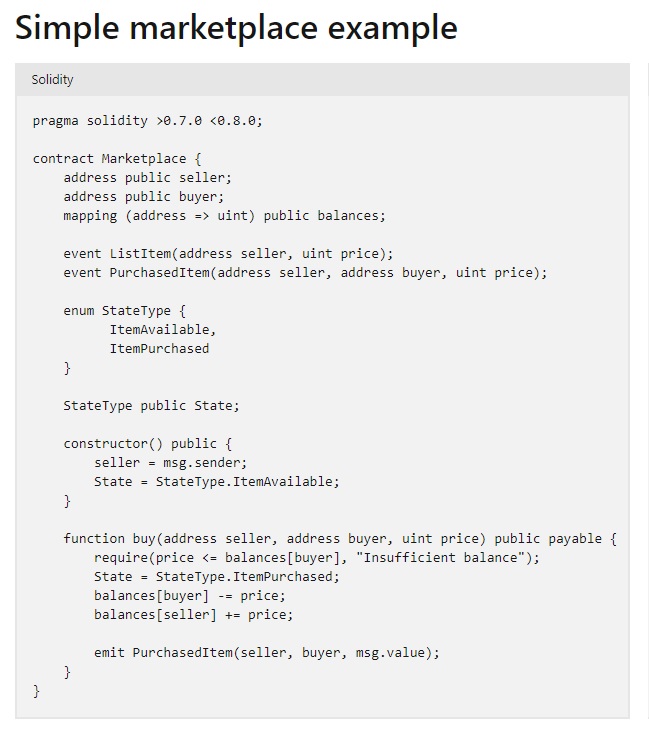

Blockchain ecosystem: Ethereum

Programming Language: Solidity

Technologies: Ganache, Truffle, Metamask, Git

Github: here

Description: Smart contract allows you to initiate a tender on the Blockchain network and submit initial commercial proposals.

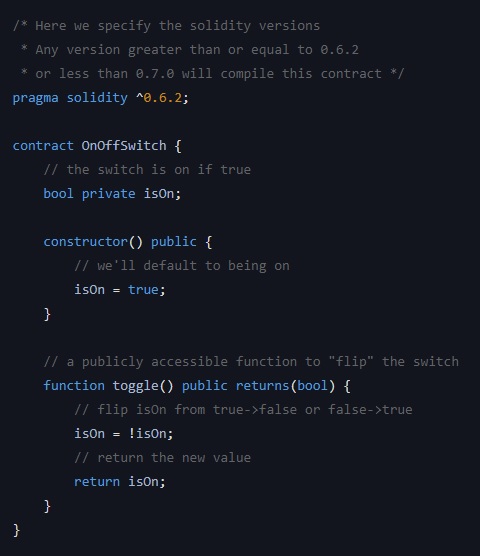

Smart Contract

Screens

Project: Registration For The Tender

15.10.2020

Blockchain ecosystem: Ethereum

Programming Language: Solidity

Technologies: Ganache, Truffle, Metamask, Git

Github: here

Description: The application allows you to register all companies to participate in the specified tender. Such registration is open and immutable. Then the specialist of the tender can eliminate the participants who did not send commercial offers.

Results

Cryptozombies

via Cryptozombies.io Platform

16.03.2020

Online Educational Course “Solidity Path: Beginner to Intermediate Smart Contracts”

The content of the modules:

Project

Coursetro

via Coursetro.com Platform

04.03.2020

Online Educational Course “Developing Ethereum Smart Contracts for Beginners“

The content of the modules:

1. What are Smart Contracts and Decentralized Apps?

2. Variables and Types

3. Creating a Web UI for our Smart Contract

4. Solidity Events

5. Function Modifiers

6. Mappings and Structs

7. Inheritance & Deployment

8. Finishing the Web3 UI

Project

University at Buffalo

via coursera.org Platform

04.03.2020

Online Educational Course “Smart Contracts“

This second course of the Blockchain specialization will help you design, code, deploy and execute a smart contract – the computational element of the blockchain technology.

Smart contracts allow for implementing user-defined operations of arbitrary complexity that are not possible through plain cryptocurrency protocols. They allow users to implement conditions, rules and policies of the domain applications. Smart contracts are a powerful feature that, when properly designed and coded, can result in autonomous, efficient and transparent systems.

You will design and program smart contracts in Solidity language, test and deploy them in the Remix development environment, and invoke them from a simple web interface that Remix provides.

This course features best practices for designing solutions with smart contracts using Solidity and Remix IDE. Main concepts are delivered through videos, demos and hands-on exercises.

Syllabus:

WEEK 1. Smart Contract Basics

The purpose of this module is to introduce the reasons for a smart contract and its critical role in transforming blockchain technology from enabling decentralized systems. We will explore the structure and basic concepts of a smart contract through examples, and illustrate Remix (remix.ethereum.org) web IDE for deploying and interacting with a smart contract.

WEEK 2. Solidity

Our goal is to master the basics of Solidity, a high-level language that is a combination of Javascript, Java and C++. It is specially designed to write smart contracts and to target the Ethereum Virtual Machine. Learners will be able to follow demonstrations and practice using Solidity.

WEEK 3. Putting it all Together

This module focuses on the development of the Ballot smart contract incrementally to illustrate various features including time dependencies, validation outside the function code using access modifiers, asserts and require declarations, and event logging.

WEEK 4. Best Practices

This module will focus on best practices including evaluating whether a blockchain-based solution is suitable for your problem, designing Solidity smart contracts, and those relating to Remix IDE.

Bitdegree

via Bitdegree.org Platform

03.03.2020

Online Educational Course “Learn Solidity with Space Doggo: an Interactive Solidity Tutorial”

The content of the modules:

Project

Altcademy

via Altcademy.com Platform

01.03.2020

Online Educational Course “Ethereum Smart Contract 101”

The content of the modules:

Project

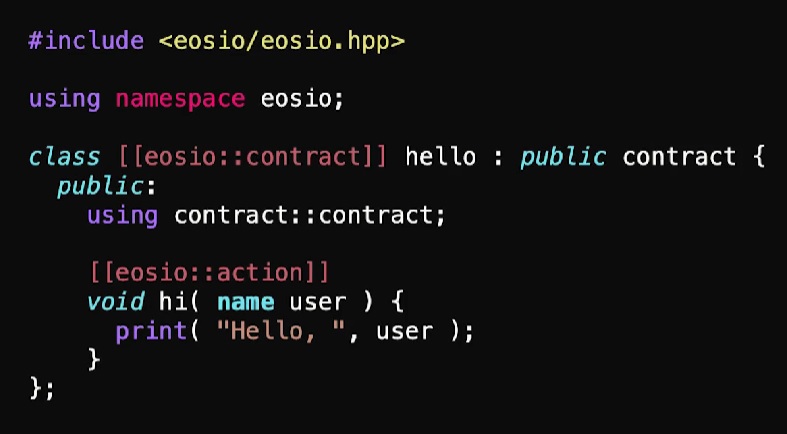

Eos.io

via Training.eos.io Platform

06.02.2020

Online Educational Course “Smart Contracts 201”

The content of the modules:

Module 1: Assets

Module 2: Receiving Transfers

Module 3: In-line Actions

Module 4: Singletons

Module 5: Bonus Lab: Add a “Pot” to Tic Tac Toe Games

Module 6: Updating Table Schemas and Migrating Data

Module 7: Getting Data from the Outside World

Module 8: Organizing Action Parameters

Module 9: Randomness

Module 10: Scheduled and Recurring Actions

Module 11: User-Friendly Resource Management

Module 12: More to Explore: Interoperability and Testing Frameworks

Eos.io

via Training.eos.io Platform

05.02.2020

Online Educational Course “Smart Contracts 101”

The content of the modules:

Project

Chainshot by Alchemy

via Chainshot.com Platform

04.02.2020

Online Educational Course “Introduction to Solidity”

The content of the modules:

Project

Web3.university

via Web3.university Platform

03.02.2020

Online Educational Course “How To Create Your First Smart Contract”

The content of the modules:

Project

Hello World smart contract from the Ethereum Foundation

// Specifies the version of Solidity, using semantic versioning.

// Learn more: https://solidity.readthedocs.io/en/v0.5.10/layout-of-source-files.html#pragma

pragma solidity >=0.7.3;

// Defines a contract named `HelloWorld`.

// A contract is a collection of functions and data (its state). Once deployed, a contract resides at a specific address on the Ethereum blockchain. Learn more: https://solidity.readthedocs.io/en/v0.5.10/structure-of-a-contract.html

contract HelloWorld {

//Emitted when update function is called

//Smart contract events are a way for your contract to communicate that something happened on the blockchain to your app front-end, which can be 'listening' for certain events and take action when they happen.

event UpdatedMessages(string oldStr, string newStr);

// Declares a state variable `message` of type `string`.

// State variables are variables whose values are permanently stored in contract storage. The keyword `public` makes variables accessible from outside a contract and creates a function that other contracts or clients can call to access the value.

string public message;

// Similar to many class-based object-oriented languages, a constructor is a special function that is only executed upon contract creation.

// Constructors are used to initialize the contract's data. Learn more:https://solidity.readthedocs.io/en/v0.5.10/contracts.html#constructors

constructor(string memory initMessage) {

// Accepts a string argument `initMessage` and sets the value into the contract's `message` storage variable).

message = initMessage;

}

// A public function that accepts a string argument and updates the `message` storage variable.

function update(string memory newMessage) public {

string memory oldMsg = message;

message = newMessage;

emit UpdatedMessages(oldMsg, newMessage);

}

}

Microsoft

via Learn.microsoft.com Platform

01.02.2020

Online Educational Course “Write Ethereum smart contracts by using Solidity”

The content of the modules:

Project

Microsoft

via Learn.microsoft.com Platform

01.02.2020

Online Educational Course “Learn how to use Solidity”

The content of the modules:

Project

Season 7. Black Ho(l/p)e

2019

Interesting and rare moments of everyday life of people in Africa will be skipped this time until Africa realizes its potential.

City Insight

Tunisia: El Jem, Hammamet, Sidi Bou Said, Sousse, Tunis, Yasmine Hammamet

Place Insight

Heritage: Carthage

Season 1. Bonus.

City Insight

Armenia: Yerevan

Azerbaijan: Baku

Belarus: Rechytsa

Georgia: Tbilisi

Kazakhstan: Almaty

Moldova: Bender, Chisinau, Tiraspol

Russia: Sergiyev Posad

Transnistria: Bender, Tiraspol

Uzbekistan: Samarkand, Tashkent

Event Insight

Military: V-Day Parade 2019

Show: Leningrad 2019, Mumiy Troll 2019, Nights Snipers 2019

Sport: Minsk 2019 2nd European Games, Sochi 2019 Formula 1 Russian Grand Prix

Season 2. Bonus.

City Insight

Portugal: Porto

Season 4. Bonus.

City Insight

Mongolia: Ulan Bator

Event Insight

Sport: China 2019 FIBA Basketball World Cup

Stats: Countries 9 (63), Cities 21 (205), Events 7 (36), Places 1 (27)

Белорусский национальный технический университет, филиал БНТУ «Институт повышения квалификации и переподготовки кадров по новым направлениям развития техники, технологии и экономики БНТУ», образовательный центр “Юниверсум”

Белорусский национальный технический университет, филиал БНТУ «Институт повышения квалификации и переподготовки кадров по новым направлениям развития техники, технологии и экономики БНТУ», образовательный центр “Юниверсум”

Минск, Беларусь

Курс повышения квалификации “Организация и проведение закупок товаров (работ, услуг) в соответствии с законодательством РБ”

Цель курса повышения квалификации – подготовка слушателей к практической работе в сфере проведения закупок, систематизация ранее полученных знаний и закрепление уже имеющихся навыков в части правил проведения закупок в соответствии с действующим законодательством Республики Беларусь.

Особенности курса:

Курс повышения квалификации относится к образовательной программе дополнительного образования взрослых и согласован с Министерством антимонопольного регулирования и торговли (уполномоченным государственным органом по государственным закупкам) в соответствии с ст. 14 п. 2 Закона Республики Беларусь от 17 июля 2018 г. № 136-З О внесении изменений и дополнений в Закон Республики Беларусь «О государственных закупках товаров (работ, услуг)».

Свидетельство:

Season 6. Amerigo Jr.

2018

Interesting and rare moments of everyday life of people in America South.

City Insight

Argentina: Buenos Aires, Cordoba

Brazil: Rio de Janeiro, Sao Paulo

Peru: Aguas Calientes, Cusco, Lima, Ollantaytambo

Event Insight

Carnivals: Rio de Janeiro 2019

Place Insight

Heritage: Machu Picchu

Season 1. Bonus.

City Insight

Russia: Nizhny Novgorod, Pskov

Event Insight

Sport: Russia 2018 FIFA World Cup

Season 2. Bonus.

City Insight

Germany: Fussen, Hohenschwangau, Ingolstadt, Munich, Nuremberg

Italy: Bologna, Calambrone, Florence, Genoa, Lucca, Maranello, Marina di Pisa, Modena, Monza, Pisa, Pistoia, Rimini, Sant’Agata Bolognese, Treviso, Turin, Viareggio

San Marino: San Marino

Event Insight

Aero: ILA Berlin Air Show 2018

Auto: Geneva International Motor Show 2018, Paris Motor Show 2018

Politics: Yellow Vests 2018

Sport: Monza 2018 Formula 1 Italian Grand Prix

Stats: Countries 4 (54), Cities 34 (184), Events 7 (29), Places 1 (26)

Smartly Institute

via Smart.ly Platform

05.08.2018

Online Educational Course “Marketing Fundamentals”

Averages, Quartiles, and the Five Number Summary

Descriptive statistics: A way to quickly summarize data within a set using just a few numbers.

Mean: The average of a set calculated by adding all the values in the set and dividing by the number of values in the set.

Outlier: A value or values significantly higher or lower than the rest of the set that can skew the mean of a set.

Median: The middle value in a data set.

Mode: The value that appears most often in the set.

When a set has two modes it is called bimodal. When it has more than two modes, it is multimodal.

Standard deviation: A measurement of the amount of variation from the mean in a data set.

For example, if a data set has a mean of 50 units and a standard deviation of 20 units, we can conclude that most of the data will fall between 30 and 70 units.

Five number summary: The minimum, first quartile, median, third quartile, and maximum of a data set.

Each quartile represents 25% of the data within a set.

The first and third quartiles can be found by identifying the medians of the lower and upper halves of the data.

Range: The distance between the maximum and minimum.

Interquartile range (IQR): The distance between the third and first quartiles.

Graphical Organization

Boxplot: A graph representing the five number summary.

The boxed area represents the IQR with the median at the center.

Frequency distribution: A table that sorts data into equally-sized classes.

Frequency: The amount of data points that fall into each class.

Cumulative frequency: The running total of the frequencies.

Relative frequency: The frequency divided by the total number of data points.

Cumulative relative frequency: The running total of the relative frequencies.

Histogram: A frequency distribution shown in graph form.

Certificate

Smartly Institute

via Smart.ly Platform

04.08.2018

Online Educational Course “Marketing Fundamentals”

Marketing Basics

Marketing: The process of creating, communicating, and delivering perceived value to customers.

Value: The practical and emotional benefits that the buyer of a product gets from it. Each benefit stems from a specific feature of the product.

Perceived value is the value that people believe they will receive from a product.

A product can be a tangible good, such as a pair of shoes, a service (e.g., a doctor’s check-up), or intellectual property (e.g., song lyrics).

Marketing strategy: A plan of what to sell, whom to sell it to, and how to sell it that is focused on long-term profit, rather than shortterm gains.

Conducting a Situation Analysis

Situation analysis: An evaluation of a company’s resources and capabilities, its competitors, and general market demand. A situation analysis consists of two tasks:

1. Examining the four C’s: company, competitors, customers, and collaborators.

2. Interpreting the information gathered in the four C’s within the framework of a SWOT analysis, which describes the company’s strengths, weaknesses, opportunities, and threats.

Segmentation, Targeting, and Positioning

Segmentation, targeting, and positioning (STP): A process used to tailor marketing efforts to relevant audiences and thus ultimately maximize revenue.

Segmentation divides consumers into distinct groups, or segments, based on homogeneity in certain attributes, distinction in these attributes from customers in other segments, and a similar reaction to marketing messages.

Targeting is the process of selecting which segment(s) of consumers to focus marketing efforts on—i.e., the target audience.

Positioning defines how a company wants its product to be perceived by consumers it markets to, relative to competing products.

Value Propositions

The value proposition (VP) is:

1. The benefits that a product provides to the target audience.

2. A statement describing these benefits.

Unique selling proposition (USP): A type of value proposition statement that communicates the essence of what makes a product unique to the target audience.

The Four P’s

The four P’s—product, price, place, and promotion—constitute the marketing mix that a company must consider in order to create a marketing strategy. These four factors are under the company’s control: the company decides what product to offer, what price to charge for it, where to place it for sale, and how to promote it. The marketing mix needs to be adjusted over the course of the product life cycle as the types of customers who buy the product and the quantity of demand change.

Positioning statement: A statement describing the core benefits that a product offers, used internally to guide product messaging.

Certificate

Smartly Institute

via Smart.ly Platform

03.08.2018

Online Educational Course “Microeconomics 1: Supply and Demand”

Introducing Microeconomics

Microeconomics: The study of how individuals, households, and firms make decisions about using limited resources.

Economic resources include:

Human resources: Workers and managers.

Nonhuman resources: Land, technology, minerals, oil, etc.

Microeconomists assume that people and firms are rational and seek to maximize benefits.

Trade-offs: Choosing one thing requires giving up another.

Scarcity: The existence of limited resources.

When an individual or group makes a decision, their opportunity cost is equal to the value of the foregone option(s).

Economic units: People, households, and firms.

Marginal benefits: Small, incremental benefits.

Supply and Demand

The law of demand: When the price of a good increases, demand for it decreases, and vice versa.

Demand schedule: Lists the quantity demanded of a product or service at various prices.

Market demand schedule: A demand schedule that encompasses the entire market’s demand for a good or service at various price points.

Demand curve (DC): Plots the quantity of a good or service demanded at different prices.

Market demand curve: Shows the market demand schedule.

When demand curves shift:

to the left—market demand has decreased.

to the right—market demand has increased.

Market price: The price at which a good or service is offered in the marketplace.

Law of supply: When the market price for a good increases, the quantity that suppliers produce and sell increases, and vice versa.

Supply schedule: Lists the quantity of a product supplied at various price points.

Supply curve (SC): Plots the supply schedule.

Market supply: The summation of all of the individual supplies of a good or service.

Market supply curve: Shows how the total quantity supplied of a good changes as its price changes.

When supply curves shift:

to the left—market supply has decreased.

to the right—market supply has increased.

Factors Contributing to Equilibrium

Equilibrium: When the amount of goods supplied is equal to the quantity demanded.

Equilibrium price: The price where equilibrium occurs ($9 on the chart).

Equilibrium quantity: The quantity where equilibrium occurs (400 on the chart).

Equilibrium point (EP): The point at which the equilibrium price is equal to the equilibrium quantity.

Price acts as a motivator:

When there is a low price for goods or services, consumers buy more and sellers supply less.

When there is a high price for goods or services, consumers buy less and sellers supply more.

Law of supply and demand: The price of any good will naturally adjust until market equilibrium is reached.

Supply > demand: There is a surplus. Prices will drop until equilibrium is met.

Demand > supply: There is a shortage. Prices will rise until equilibrium is met.

Supply = demand: The market has reached equilibrium.

To recognize events that alter equilibrium:

1. Identify a shift in the DC and/or the SC.

2. Determine if the curve(s) shift left or right.

3. Use a graph to see how the shifts change the EP.

Certificate

Smartly Institute

via Smart.ly Platform

02.08.2018

Online Educational Course “Accounting 1: Fundamentals”

Introducing the Balance Sheet

All companies must follow a set of rules that standardizes the reporting and recording of their financial data.

While US companies follow Generally Accepted Accounting Principles (GAAP), companies in most other countries follow the International Financial Reporting Standards (IFRS). The balance sheet gives a glimpse into the health and composition of a business.

Double-entry bookkeeping: A transaction requires at least two entries to keep the balance sheet balanced.

Dual-aspect concept: If there is a change in the total amount of assets, there needs to be a resulting change in liabilities, equity, or both.

Money-measurement concept: Only items expressed as monetary amounts can go on a balance sheet.

Entity: A business, company, or organization.

Entity concept: A business’ finances are separate from its owner’s finances.

Going-concern concept: Accounting assumes that an entity will operate indefinitely.

Assets, Liabilities, and Equity

Assets: Items owned and controlled by an entity, valuable to the entity, and acquired at a measurable cost.

Current assets are assets expected to be converted into cash or used up by the business within one year.

Accounts Receivable: Where a company records credit purchases by its customers. The company expects these customers to pay them in cash in the near future.

Inventory: Goods an entity intends to sell.

Prepaid Expenses: Monies paid in advance for pending expenses—for example, paying rent in advance. Noncurrent assets will not be used up or converted into cash for at least one year.

Property, Plant and Equipment (PP&E): Tangible assets that depreciate, or lose value, over time due to wear and tear.

Creditor: Anyone who lends money or extends credit.

Liabilities: Debts owed to outside entities (creditors) in return for borrowed goods, services, or monies.

Current Liabilities: Obligations that will be paid within one year.

Long-Term Liabilities: Obligations that won’t be paid until at least a year has passed.

Bank Loans (Bank Loan Payable) can be recorded under both current and long-term liabilities.

Accounts Payable: Obligatory monies owed by an entity for goods and services. The opposite of Accounts Receivable.

Estimated Tax Liability: The estimated amount of what will be due in taxes per year.

Equity: Money (capital) either supplied by equity investors or collected in the form of an entity’s retained earnings.

Paid-In Capital: Money supplied by investors.

Retained Earnings: Income generated by an entity’s successful operations that is reinvested in the entity.

Proprietorship: An entity with one sole owner and investor.

Account Types

T-accounts: Charts used to record increases and decreases of individual accounts found on the balance sheet.

Debits: Represent an increase in an asset but a decrease in a liability or equity.

Credits: Represent a decrease in an asset but an increase in a liabilty or equity.

Asset accounts will normally have debit balances. Liability & Equity accounts will normally have credit balances.

Two special equity accounts are Revenues and Expenses. Revenues are increases in equity and usually have a credit balance. Expenses are decreases in equity and usually have a debit balance. Revenues are debited and credited like other equity accounts, but Expenses are debited and credited like asset accounts.

Accounting Transactions

Income Statements are used to calculate net income.

Net Income: The difference between total revenues and total expenses.

Net Income = Total Revenues — Total Expenses

Balance Sheets record one point in history and show a company’s financial position. Income Statements measure a company’s financial performance over a period of time.

General Journal: The chronological record of every transaction. A journal uses the same rules as a T-account.

General Ledger: The collection of all T-accounts.

Revenues and Expenses are temporary accounts. At the end of a period they are closed out and their balances are transferred to the income statement. Other asset, liability, and equity accounts are permanent accounts. They are not closed out, and their balances are transferred to the balance sheet.

Certificate

Smartly Institute

via Smart.ly Platform

01.08.2018

Online Educational Course “Finance: Time Value of Money”

Present Value and Future Value

Time value of money: Money in the present is worth more than the same amount of money in the future.

Present value: The value of a sum of money today. Present value calculations move money backwards in time.

Future value: The value of a sum of money at a specific time in the future. Future value calculations move money forwards in time.

The Timeline

Timeline: A tool used for visualizing a time value of money scenario. The periods of a timeline must always be equal.

Inflows of cash are positive numbers and outflows of cash are negative numbers.

Compounding and Discounting

Compounding is the process used to move money forward in time:

Increases the value of a sum of money

Involves multiplication

Calculates future value

Discounting is the process used to move money backward in time:

Decreases the value of a sum of money

Involves division

Calculates present value

Net Present Value

Net present value (NPV): The difference between the present value of all benefits and present value of all costs of a particular investment.

Benefits are represented by cash inflows (positive).

Costs are represented by cash outflows (negative).

Net present value is represented by this equation:

NPV = PV(benefits) – PV(costs)

A positive NPV (inflows > outflows) is an indication that a firm should invest in a project.

Moving Money Over Time

To compare or combine cash flows, they must be moved forward or backward to the same point in time.

Certificate

Georgia Institute of Technology

via coursera.org Platform

10.06.2018

Online Educational Course “Supply Chain Principles“

This course will provide a solid understanding of what a supply chain is all about. The course:

– Provides an introduction to Supply Chain

– Leverages graphics to promote the Integrated Supply Chain model

– Emphasizes understanding the Extended Supply Chain

– Presents a holistic approach – Incorporating People, Process, and Technology

– Calls-out industry-specific supply chain

– Leverages discussions, videos, quizzes, and questions for consideration

– Provides awareness of career path opportunities

– Presents emerging and futuristic trends in supply chain and given that at GT we are focused on developing what’s next in the world, we include Discussion of emerging and futuristic trends in supply chain.

There is very little math involved in this course – so don’t worry at all about your math skills.

The course incorporates reading materials that were developed as part of a $24.5M TAACCCT grant awarded by the U.S. Department of Labor’s Employment and Training Administration to the LINCS in Supply Chain Management consortium.

This course is designed for a wide range of learners including:

– Individuals working in a supply chain domain interested in improving their knowledge of supply chain

– Individuals curious about pursuing a career in supply chain

– Students working or studying in an adjacent business field

– Seasoned professionals who may be moving to a new area of supply chain

– Hobbyists – seeking to learn more about the world around them

World Bank Academy

10.06.2018

Online Educational Course “e-Procurement Learning”

This e-Learning course is designed to provide participants with an in-depth understanding of the concept of public procurement and e-Government Procurement (e-GP) and how e-Procurement solutions can be designed and implemented in a more effective and economical way. This course outlines how to prepare a strategy for establishing an e-GP framework and presents in detail basic and advanced tools of e-Procurement systems. Moreover, it describes the need for the establishment and use of public procurement indicators, as well as how public financial management can be strengthened through the incorporation of procurement and e-Procurement into PFM reform projects.

Course overview

E-Government procurement (e-GP) projects are often part of the wider e-government efforts of countries to efficiently and effectively serve their citizens and businesses. E-GP promotes better governance in public procurement by increasing transparency and eliminating opportunities for fraud and corruption. The application of ICT to procurement processes has resulted in e-Procurement platforms that are ideally suited to address the e-GP objectives.

Pursuing an e-Procurement system implementation is an effective way to improve public procurement management, through the automation of all underlying processes. Many governments worldwide have adopted end-to-end e-Procurement systems which cover the full procurement cycle.

The current e-Learning course is composed of five modules, aiming to assist its audience to better understand electronic procurement and provide them with guidance on decisions they may need to take for establishing or improving the e-GP framework of their countries.

The course initially focuses on how organizations can establish a plan for an e-GP implementation, and what benefits can be expected by such an implementation project. Furthermore it provides an overview of the basic and advanced features and modules of e-Procurement systems, along with concise information on how to implement each of the described e-Procurement modules.

Additionally, the course briefly describes e-Procurement indicators and presents how these can be used by governments in order to measure adoption, performance and overall governance. Lastly, it focuses on how to incorporate procurement and e-procurement into FMIS implementations in the context of PFM reform projects.

At the end of this course, a certification can be obtained by those participants who complete the course and successfully pass the respective examination.

Course features

The course is composed of the following modules:

Target audience

The learners should at least have an understanding of the national public procurement setting and the EU public procurement procedures as well as a high-level view of web-based applications and software implementation projects.

Score

Certificate

Ministry of Business, Innovation and Employment, NZ

05.06.2018

Online Educational Course “Demystifying Procurement”

Demystifying Procurement is an introductory online course that gives you tools and techniques to help you with your procurement.

This introductory course is especially useful for:

Course outline

This free introductory training course covers the eight stages of the procurement life-cycle in four short modules.

By the end of the course you should have an understanding of:

There are four self-paced modules with interactive graphics and tables, links to procurement tools and guidance on this website and practice questions at the end of each section.

Module 1 covers the project initiation, needs and market analysis sections of the planning phase. The module will take you through identifying and understanding key stakeholders and their needs, putting together a project team, probity considerations and understanding the supply market.

Module 1 should take about 30 minutes to complete.

Module 2 covers the specification of requirements and planning approach to market sections of the planning phase. The module will take you through key considerations when specifying your requirements, determining which approach to market strategy is right for the procurement, evaluation methodology, what should go into the procurement plan and starting to think about the contract construct.

Module 2 should take about 30 minutes to complete.

Module 3 covers the sourcing phase of the procurement life-cycle, including approach to market; supplier selection and contract negotiation and award. The module will take you through what needs to go into your RFx documentation, publishing a notice of procurement, convening the evaluation panel and evaluating responses, negotiation theory, contract arrangements and debriefing unsuccessful respondents.

Module 3 should take about 50 minutes to complete.

Module 4 covers the manage phase of the procurement life-cycle, including managing the contract and relationships and reviewing procurement outcomes. The module will take you through the three key elements of contract and relationship management, the relationship spectrum, dispute resolution considerations and the review cycle.

Module 4 should take about 25 minutes to complete.

Alison

via Alison.com Platform

03.06.2018

Online Educational Course “Forecasting – Winter’s Models, Goodness of forecast, Aggregate Planning, Tabular Method”

by G. Srinivasan

Learn how aggregate planning is used in many businesses to match supply and demand of output over the medium time range of up to approximately 12 months in the future by studying the course Applied Operations Management – Aggregate Planning.

Aggregate planning allows management to quantify materials and other resources that are to be procured so that the total cost of operations are kept to the minimum over a set period of time. The course begins by introducing the concept of aggregate planning and its use in medium term planning in businesses. You will be introduced to aggregate planning methodologies such as the tabular method and linear programming.

You will learn how a tabular approach uses spreadsheets and the values of different variables, such as production by regular workforce and inventory levels can be calculated by using the costs associated with production, overtime, subcontracting, hiring, inventory and back-orders. The tabular method is widely used because it is easy to understand and utilize. However, the generated solution may not be optimal and many trials and errors may be needed to find the optimal solution. The course also introduces the linear programming technique and a special type of linear programming known as the Transportation Model, which can be used to obtain aggregate plans that would allow balanced capacity and demand and the minimization of costs.

This course will be of great interest to all professionals working in the areas operations management or general management who would like to learn more about aggregate planning and the methods used in this important area of operations management. The course will also be of interest to all learners who are interested in operations management as a future career.

The key points from this module are:

Forecasting can be defined as the estimate of future demand.

Aggregate planning is carried out once information about future demand is obtained from forecasting.

A poor Aggregate Plan can result in the following:

– Lost sales and profits if unable to meet demand

– A large amount of excess inventory and capacity which increases costs

The question ‘What should the production capacity be such that the total production cost is minimized?’ is known as the aggregate planning problem.

The following costs are used to calculate the minimum production capacity production cost:

– Regular Time cost

– Overtime cost

– Inventory cost

– Shortage cost

The formula for Total Capacity is:

Total Capacity = Regular Time Capacity + Overtime Capacity

Regular time production is assumed to be less costlier than overtime production. Back order cost can be defined as the cost of back ordering per unit per month. Increasing or decreasing the number of production employees does not affect the regular time production capacity.

Linear Programming

R(t) – Regular Time production used in time t

O(t) – Overtime production used in time t

D(t) – Demand during time t

S(t) – Shortage at the end of period t

U(t) – Under utilization in period t

H(t) – Number of people hired in period t

W(t) – Number of people working in period t

L(t) – Number of people laid off in period t

In the linear programming formulation ‘I(t)’ (the inventory at the end of the previous period) has to be defined as a unrestricted variable which can take positive value or a negative value. Linear programming is a method to achieve the best outcome (such as maximum profit or lowest cost) in a mathematical model whose requirements are represented by linear relationships. In aggregate planning the planning horizon is often divided into Periods. The physical resources of the company are assumed to be fixed during the planning horizon of interest.

The following help a company cope with demand fluctuations:

– Changing the size of the work force by hiring and firing.

– Varying the production rate by introducing overtime.

– Accumulating seasonal inventories.

– Planning backorders.

The following costs are relevant to aggregate production planning:

– Basic production costs

– Costs associated with changes in the production rate

– Inventory related costs

In aggregate production planning the following are examples of basic production costs

– Material costs

– Direct labor costs

– Overhead costs

In aggregate production planning the following are costs associated with changes in the production rate:

– Hiring costs

– Training costs

– Laying off personnel costs

In the Aggregate Planning Problem the following are examples of constraints:

– Limits on overtime

– Limits on layoffs

– Limits on capital available

– Limits on stockouts and backlogs

Score

Alison

via Alison.com Platform

03.06.2018

Online Educational Course “Inventory Models – Costs, EOQ Model”

by G. Srinivasan

Inventory Management – Using Inventory Models is the fourth in the Applied Operations Management series of courses. Inventory models help businesses answer the questions: How much material to order? When to order the material? They help firms determine the order quantity that minimizes the total inventory holding costs and ordering costs, as well as the frequency of ordering, to keep goods or services flowing to the customer without interruption or delay.

The course begins by introducing the basics of inventory management and introduces concepts such as deterministic demand and probabilistic demand, type of costs such as cost of item, order cost, and holding or carrying cost. Several models are available to help determine how much inventory should be brought in to restock the products or parts, and you will be introduced to inventory models such as the single period inventory model, the multi-period inventory model and the economic order quantity (EOQ) model. These models are explained in detail using worked examples.

This course will be of great interest to professionals working in the area of inventory management, procurement and operations management and who would like to learn more about using inventory models. The course will also be of interest to learners who are interested in a career in procurement or operations management.

The key points from this module are:

Economic order quantity (EOQ) model is the order quantity that minimizes the total inventory holding costs and ordering costs.

Several extensions can be made to the EOQ model developed by Mr. Pankaj Mane, including backordering costs and multiple items.

The EOQ model solves the “how much” and “when” aspects of ordering inventory. When inventory reaches the zero point, you order just enough to replenish your stock back to its original level.

You repeat this cycle throughout the year, never having to decide when to order or how much to order.

The EOQ model assumes that demand remains steady throughout the year and that inventory gets used at a fixed rate. If those assumptions hold true, you can order at the same time each month or quarter.

However, if demand fluctuates, you may run out of inventory sooner than you anticipate. You also may have to order more than you usually do to meet higher demand, or lower the order to adjust to declining demand.

The EOQ will sometimes change as a result of quantity discounts, which are provided by some suppliers as an incentive for customers to place larger orders.

Score

Alison

via Alison.com Platform

03.06.2018

Online Educational Course “Supply Chain Risk”

by N. Viswanadham

The course Understanding Supply Chain Risk Management (SCRM) introduces the learner to the multitude of risks that threaten the operation of supply chains at national and global levels. A previous course – Understanding Supply Chain Ecosystems – looked at Supply Chain Ecosystems and supply risk involves adverse and unexpected changes to any elements of a supply chain ecosystem.

The aim of SCRM is to reduce supply chain vulnerability by identifying and managing risks within the supply chain and external to it. The course gives examples of resource uncertainties, characteristics of Wicked problems, and describes the elements of a cyber attack. It also lists the six strategies to reduce overall risk exposure.

This course will be of great interest to all professionals who work in the areas of operations management, logistics, procurement and information technology, and to all learners who are interested in developing a career in the area of supply chain management.

Score

Alison

via Alison.com Platform

03.06.2018

Online Educational Course “The Supply Chain Eco-System Framework”

by N. Viswanadham

Supply Chain Ecosystems are made up of a network of organizations, people, activities, information, and resources all of which are involved in moving a product or service from supplier to customer.

The course begins by describing how modern supply chains have evolved into complex international networks, which can no longer be adequately described using the linear concept of a ‘chain’. The course then reviews how modern supply chain ecosystems now comprise of a network of companies, countries and their governments, social and political organisations, natural, industrial (clusters), financial and human resources, delivery infrastructure including logistics and IT, and knowledge of the industrial environment. You will learn how within these ecosystems, each configuration is unique to the particular enterprise that owns that supply chain.

This course will be of great interest to all professionals who work in the areas of operations management, logistics, procurement and information technology, and to all learners who are interested in developing a career in the area of supply chain management.

The key points from this module are:

The Ecosystem Model: A framework to visualize all Operational, Strategic, Management and Execution issues.

Ecosystems comprise of a network of:

Companies, countries and their governments, Social and political organisations

Natural, Industrial (clusters) and Financial and Human resources

Delivery infrastructure including logistics and IT

Connections, and knowledge of the industrial environment.

All interacting together with the landscape and climate (economic and industrial).

Supply chain ecosystems consist of:

Institutions

Resources

Delivery Services infrastructure

Supply Chain

Institutions:

Customs, Export and Other Govt. Regulators

Quality Control and Environmental issues

Social, Financial and Trade issues

Resources:

Infrastructure, Sea ports, Airports, Roads

Industry clusters

Human, Financial and Natural resources and labor unions

Delivery Services infrastructure:

Logistics and IT companies

Transport – Rail, Air, Ship, Road

Logistics parks, SEZs, Freight corridors

Supply Chain:

Retail chains

Distribution

Manufacturing

SuppliersDrivers of Supply Chain Competitiveness

Resources: Labour, Materials and Energy

Government policies and investments on institutional, environmental and infrastructural elements

Delivery mechanisms: Logistics and IT

SES Framework can hep to study:

Governance

Risk

Innovation

Performance

The Five STERM Forces:

Science research

New Technologies

New Engineering materials

Regulations and policies

New Management techniques

Modular Product:

– Made by appropriately combining different modules.

– Provides customers a number of options for each module and thus the product.

– Products differ from each other in terms of the subsets of modules assembled to produce them.

Modular Process:

– Each module undergoes a specified set of operations making it possible to outsource its manufacturing and inventory to them in a semi-finished form.

Part Standardization:

– Common parts are used across many processes

– Products redesigned as necessary

Process Standardization:

– Standardizing as much of the process as possible, making a generic or family product.

– Final product assembly delayed until the customer order is received (i.e. called “postponement”).

Modular Organization Designs

Modularization of product designs paves the way for similar modularization of organization designs facilitting coordination of activities via an “information structure” rather than managerial authority or hierarchy.

The codification of knowledge and standardization (through technical standards and design rules) of the interfaces between organizationally separate stages of production has made vertical specialization (organizational modularity) replace vertical integration.

Types of Resources

Classical economics define:>

– Natural resources

– Human resources

– Financial resources

– Capital assets

Modern view also includes:

– Knowledge, Intellectual property

– Social capital relationships with stake holders

– Management of high value delivery processes

Special Economic Zones (SEZs)

SEZ is a geographical region that has economic laws different from the rest of the country. The goal of SEZs is to attract foreign investments. SEZs have been established in many countries – China, India, Jordan, Poland, Philippines, Russia and North Korea. Indian SEZs are not as effective as those in China probably because they are not as focused.

Clusters

Clusters are geographic concentrations of interconnected companies, specialized suppliers, service providers, and associated institutions (universities, training) in a particular vertical.

Clusters allow companies to operate more productively in sourcing inputs; accessing inforamtion, technology and human resources.

Score

Alison

via Alison.com Platform

29.05.2018

Online Educational Course “Global Supply Chain ReDesign”

by N. Viswanadham

It is said that in today’s market, firms don’t compete, supply chains do, and supply chain design can give supply chains a competitive advantage over competing supply chains. The course begins by explaining what supply chain design is, the importance of supply chain design and the design process itself. You will learn how supply chains determine the ability of the businesses included in them to compete, and the design of their supply chains will affect their ability to compete in the marketplace. For example, a business that is attempting to compete in a market where low cost is paramount will have difficulty if it includes high cost suppliers in its supply chain.

This course will be of great interest to all professionals who work in the areas of operations management, logistics, procurement and information technology, and to all learners who are interested in developing a career in the area of supply chain management. Prerequisites: It is recommended that you have studied the courses ‘Introduction To Supply Chain Management – Revised 2018’, and ‘Understanding Supply Chain Ecosystems – Revised 2018’.

The key points from this module are:

Current day supply chain networks are subjected to disruptions and innovations in the ecosystem elements, resources and other factors.

Disruptions can originate from the banks, governments, bankruptcy of the supplier’s suppliers, natural disasters, piracy, cyber attacks, port strikes and other unknown factors.

Innovations in products, manufacturing and delivery processes, business models, government to government relations such as Free Trade Agreements, regulations and deregulations and many more affect the supply chain.

Global Supply Chain design involves two steps:

1) Global supply chain formation

2) Building Governance mechanisms or frameworks for partner selection, coordination and control

Global Supply Chain Formation:

1) Map the supply chain ecosystem for the industry vertical

2) Formulate the supply chain strategy

3) Select possible locations for the factories

4) Identify the supply chain risks

5) List the feasible supply chain configurations

The Governance Function involves:

Partner selection from group of pre-selected suppliers from Supply Chain Formation stage

Coordination – Determining who does what and when and communicating to everyone

Execution – Build a control tower to monitor order status so that processes work as per plan and control exceptional events

Business Model Innovation (BMI) is a reconfiguration of activities in the existing business model of a firm that is new to the product/service market in which the firm competes.

Clusters are geographic concentrations of interconnected companies, specialized suppliers, service providers, and associated institutions present in a region.

The proximity of companies and institutions in one location fosters better coordination and trust lowering the transactions costs, minimizing the inventory, importing costs and delays.

Types of Supplier Asset Specificity

Physical asset specificity refers to the mobile and physical features of assets such as specific dies, molds, and tooling for the manufacture of a contracted product.

Dedicated asset specificity represents discrete and/or additional investment in generalized production capacity in the expectation of making a significant sale of a product to a particular customer.

Human asset specificity arises in a learning-by-doing fashion through long-standing customer-specific operations.

Site asset specificity refers to the successive stages that are immobile and are located in close proximity to one another so as to economize on inventory and transportation.

Global Competitiveness Indicators – Based on which countries are evaluated include:

– National Policies for Openness in Trade and Markets

– Best Practices for International Trade

– Effective Legal and Enforcement Systems

– Infrastructures for a Global Economy

– Financial Services for Cross-Border Commerce

– Human Capital

Risks to supply chain ecosystems include all possible social, political and environmental risks that may affect the ecosystem and the flows of goods, information and finance.

Risks to Supply Chains:

– Outsourcing

– Mergers or acquisitions

– Large scale and a high degree of concentration

– Political and societal risk

– Resource intensive shortages

Transaction costs include:

Observable costs – Transport costs, import duties, customs tariffs and other formal trade barriers

Soft costs – Costs for information gathering, negotiation and monitoring contracts, trust building, networking, risk handling and mitigation, making up for cultural differences and miscommunication, compliance with safety regulations, labor laws etc.

Three characteristics of transactions affect the transaction costs:

– Asset specificity

– Uncertainty

– Frequency

Transaction Cost Economics (TCE) Theory:

When transaction cost are low, use the spot market governance

When transaction costs are high, hierarchy is efficient

Asset Specificity: Supply chain specific assets, Resources, Institutions, Delivery infrastructure.

Environmental uncertainty can come from suppliers, customers, competitors, regulatory agencies, unions or financial markets.

Frequency of interactions between the buyer and supplier is importance for reasons of economies of scale.

Score

Season 5. Usa Canada Cuba Mexico here

Season 5. Usa Canada Cuba Mexico here

2017

Interesting and rare moments of everyday life of people in America North.

City Insight

Canada: Niagara Falls

Mexico: Cancun, Mexico City, Valladolid

Usa: Boston, Buffalo, Cambridge, Chicago, Cleveland, Cupertino, Deaborn, Detroit, Jersey City, Las Vegas, Los Angeles, Miami, Miami Beach, Mountain View, New York, Newark, Niagara Falls, Oakland, Orlando, Palo Alto, Philadelphia, Pittsburgh, San Francisco, Santa Monica, Washington

Event Insight

Auto: North American International Auto Show 2018

Place Insight

Heritage: Chichen Itza, Teotihuacan

Wildlife: Grand Canyon, Niagara Falls

Space: Kennedy Space Center

Season 1. Bonus.

City Insight

Kyrgyzstan: Bishkek

Event Insight

Aero: MAKS 2017

Season 2. Bonus.

City Insight

Belgium: Bruges, Brussels, Charleroi

Catalan Republic: Barcelona

Finland: Helsinki

Germany: Frankfurt, Stuttgart, Wolfsburg

Iceland: Reykjavik

Luxembourg: Luxembourg

Portugal: Lisbon

Spain: Madrid

Switzerland: Bern, Buchs, Lucerne, Zurich

Event Insight

Auto: Frankfurt International Motor Show 2017, Brussels Motor Show 2018

Place Insight

Heritage: Neuschwanstein Castle

Wildlife: Alps

Stats: Countries 12 (50), Cities 50 (150), Events 4 (22), Places 7 (25)

17.10.2017

Energy Discovery Centre, Tallinn, Estonia

2017 Procura+ Awards on Sustainable and Innovation Procurement with support of ICLEI and European Commission recognise three categories of excellence: Sustainable Procurement of the Year, Innovation Procurement of the Year, and Tender Procedure of the Year.

Promo:

Photos:

Conference on Innovation Procurement

Conference on Innovation Procurement

17.10.2017

Kosmos IMAX, Tallinn, Estonia

The Conference on Innovation Procurement took place under the Estonian EU presidency on 17th and 18th of October 2017 in Tallinn, Estonia. The Conference also served as the 3rd annual Major eafip Event. The conference programme included:

The target audience for the two-day conference was policy makers, public procurers and innovators. Its aims were capacity building, experience sharing and networking about major ICT-related innovation procurement initiatives across Europe and to facilitate networking between stakeholders to discuss new ideas, initiatives and funding opportunities.

The event was co-organised by the Estonian Ministry of Economic Affairs and Communications (MEAC) and the Directorate-General for Communications Networks, Content and Technology (DG CNECT) of the European Commission (EC). The conference was supported by the European Union Regional Development Fund. The 2017 Procura+ Awards were supported by the EU’s Horizon 2020 Programme, and co-ordinated by ICLEI.

Welcoming words:

Urve Palo, Minister of Entrepreneurship and Information Technology, Estonia

Presentations:

Keynote – How to mainstream innovation procurement in Europe?

Gerard de Graaf, Director, Digital Single Market Directorate, DG CNECT, European Commission

Public procurement of innovation – the policy logic behind the strategic use of procurements

Veiko Lember, Senior Research Fellow, Tallinn University of Technology, Estonia

e-solutions in Estonia – living proof of innovation procurements

Andres Kutt, Former advisor, Information System Authority, Estonia

Panel discussion: Innovation procurement as driver for economic growth and address secretol challenges

Moderator: Gaynor Whyles, Director, JERA Consulting Ltd

Helen Kopman, Deputy Head of Unit, Start-ups and Innovation Unit, Digital Single Market Directorate, DG CNECT, European Commission

Andreas Nemec, Managing Director, Federal Procurement Agency BBG, Austria

Evelin Porn-Lee, Tallinn University of Technology, Estonia

Kalev Pihl, CEO, SK ID Solutions, Estonia

Session: Innovation procurement experiences (Examples and analysis of innovation procurements across Europe)

Moderator: Gaynor Whyles, Director at JERA Consulting Ltd

Innovation methods for award procedures of ICT learning in Europe. IMAILE

Ellinor Wallin, IMAILE project manager. Sweden

Teemu Laitinen. CEO Almerin. Finland

Andrea Contino. AMIGO. Spain

Sweden’s electric roads for heavy vehicles pre-commerciol procurement

Anders Bylund, Head oi Rail and Road Electrification. Siemens Mobility. Sweden

London underground PROLITE lighting PPI procurement, winner of the PROCURA+ Award Innovation Procurement of the Year 2016

Leon Smith, Manager technology and innovation, Transport for London, UK

David Bide, Commercial Director, Armadillo-ED — Evolution in Lignting. UK

Telemedicine for Intensive Care Units procurement, THALEA

Dr. Gernot Marx, Professor ot Anesthesrology and Critical Care Medicine and Chair at the University RWTH Aachen, Germany

Panel discussion: Benchmarking the progress on innovation procurement across Europe: EU member states (Austria, Finland, Estonia, and European Commission) policy and measurement framework for innovation procurement

Moderator; Gaynor Whyies, Director, JERA Consulting Ltd. UK

Eva Buchinger, Policy Advisor. Austrian Institute at Technology. Austria

Ville Valovirta, Senior Screntist, lnnovations, Economy and Policy,VTT Technical Research Centre of Finland. Finland

Paul Jackson, Innovation procurement policy expert, Ministry of Economic Alloirs and Communications. Estonia

Vasileios Tsanidis, Policy Ollicer. DG Communications Networks, Content and Technology. Directorate F Digital Single Market, European Commission

Promo:

Академия управления при Президенте Республики Беларусь, Институт государственной службы

Минск, Беларусь

Курс повышения квалификации “Организация и проведение закупок товаров (работ, услуг) в строительстве и закупок за счет собственных средств”

Преподаватели:

Бенсман М.В., Амельченя Ю.А., Богатко А.В., Полящук Н.А., Вашкевич И.Ф., Бакиновская О.А.

Разделы:

Свидетельство:

New York Consulting Procurement Conference 2017

29.06.2017

American Management Association Times Square, New York, USA

The New York Consulting Procurement Conference is one-of-its-kind event that allows Executives interested in Procuring Consulting Services to connect with peers and experts of the domain to exchange about challenges, best practices and trends in the Consulting industry.

Presentations

What is innovation in the Digital Environment? George Hemingway, Partner at Stratalis Consulting

The impact of digital transformation on Organization. Thomas Bertels, Partner at Valeocon Management Consulting

How can traditional banks leverage Fintech practices to compete in a digital world? Bijon Mehta, President at Association of FinTech Professionals

Digital in Manufacturing Industries : Supply chain 2.0 ? What else ? Laurent Thomas, VP Strategy at Solvay Novecare

Digitalizing Procurement : Deja vu ? Rajiv Gupta

How digital is transforming Consulting Services ? David Tang, CEO of Flevy

Photos

Международная конференция “Управление корпоративной задолженностью”

17 февраля 2017

Марриотт Москва Гранд Отель, РФ, Москва, Тверская, 26/1

Данная конференция представляет участникам лучшие практики профилактики и своевременного отслеживания возникновения проблемной задолженности и ведущие практики реструктуризации проблемных долгов, позволяет проанализировать эффективность внутренней службы взыскания долгов vs. коллекторское агентство, а также узнать об эффективных схемах взыскания корпоративной задолженности.

Выступления:

1. Дмитрий Жданухин, президент Ассоциации корпоративного коллекторства

Работа с корпоративными долговыми проблемами: уроки очередного кризиса

2. Сергей Кюрегян, директор по развитию Мосэнергосбыт

Работа с задолженностью по ЖКУ

3. Наталья Петрушина, главный специалист Департамента корпоративных финансов РЖД

Управление оборотным капиталом компании

4. Наталья Дорошенкова, директор КПМГ

Реструктуризация долга: взгляд со стороны компании

5. Евгений Еськин, компания М-Видео

Блокчейн-верификация долга в факторинге

6. Ольга Зимина, начальник службы взыскания долгов СТА Логистик

Эффективные инструменты управления дебиторской задолженностью

7. Людмила Клименко, руководитель по методологии и управлению процессами взыскания дебиторской задолженности клиентов Мегафон

Автоматизация процессов взыскания дебиторской задолженности

8. Анастасия Аминова, менеджер по финансовому контролю AUCHAN

Работа с коллекторскими агенствами

9. Николай Мышковец, начальник отдела казначейства Asstra

Эффективные инструменты взыскания дебиторской задолженности и финансирования кассового разрыва

10. Дмитрий Аверьянов, управляющий процессным офисом Аксиома-Авес

Роботизированное управление проблемными договорами

11. Анна Глазкова, заместитель генерального директра по экономике и финансам ФОРТ

Стратегии досудебного урегулирования просрочки

12. Иван Тактаев, заместитель директора по правовым вопросам НПО Петровакс Фарм

Доказывание факта поставки как основания возникновения задолженности – проблемы судебной практики

13. Конкурс решений корпоративных долговых проблем

Журналы:

Стартап-школа “Гомель”

15 февраля 2017

Гомель

Выступления:

1. Антон Шалейников “Управление в “Стартапе”

Стартап-школа “Гомель”

08 февраля 2017

Гомель

Выступления:

1. Кирилл Волошин “Создайте свою историю успеха”

2. Неформальное бизнес-обучение

Season 4. AsiaTown

2016

Interesting and rare moments of everyday life of people in Asia.

City Insight

Cambodia: Siem Reap

China: Beijing, Hong-kong, Shanghai

India: Abhaneri, Agra, Amer, Delhi, Fatehpur Sikri, Jaipur, Vrindavan

Malaysia: Kuala Lumpur

Singapore: Singapore

Vietnam: Hanoi

Place Insight

Heritage: Angkor Wat, Great Wall of China

Wildlife: Ha Long Bay

Event Insight

Sport: Pattaya 2016 Muay Thai Ultimate Tournament

Season 1. Bonus.

Event Insight

Auto: Moscow International Automobile Salon 2016

Military: V-Day Parade 2016

Sport: Moscow 2016 IIHF Ice Hockey World Championship

Stats: Countries 8 (38), Cities 19 (100), Events 4 (18), Places 3 (18)

Международная конференция “Финансирование цепочки поставок и факторинг”

27 октября 2016

Марриотт Москва Гранд Отель, РФ, Москва, Тверская, 26/1

Данная международная конференция собирает профессионалов в области привлечения финансирования и управления оборотным капиталом компаний для обсуждения целесообразности использования инструментов Supply Chain Finance, а также отвечает на вопросы о том, как повысить финансовую эффективность цепочки поставок, оптимизировать оборотный капитал компании и уменьшить дебиторскую задолженность.

Выступления:

1. Андрей Мороков, специалист отдела обеспечения производства РУП Белоруснефть

Финансирование цепочки поставок в крупных промышленных компаниях.

2. Анастасия Аминова, менеджер по финансовому контролю AUCHAN

Повышение финансовой эффективности цепочки поставок.

3. Дмитрий Шевченко, исполнительный директор Ассоциации факторинговых компаний

Прогнозы развития рынка факторинга в России

4. Антон Шаев, заместитель финансового директора Альтерпласт

Опыт внедрения факторинга в компании оптовой торговли

5. Мурат Ошроев, управляющий партнер Willance

Обзорное выступление

Журналы:

Международная конференция “Лизинг 2016”

15 – 16 сентября 2016

Отель Яхонты, Подмосковье

Выступления:

1. Евгений Царев, директор НП “Лизинговый союз”

2. Олеся Губка, финансовый директор Агромаркет

Риски лизингополучателя

3. Лариса Ефремова, вице-президент Объединенной лизинговой ассоциации

Отраслевой стандарт учета договоров аренды для некредитных организаций и что необходимо знать с вводом нового IFRS 16 “Аренда”

4. Дмитрий Костальгин, управляющий партнер Taxadvisor

Налогооблажение лизинга

5. Михаил Кожарин, главный менеджер по финансированию и инвестициям ОДК-Газовые турбины

Корпоративная практика применения лизинга

6. Анна Глазкова, заместитель генерального директора по экономике и финансам ФОРТ

Лизинг в проектном финансировании

Журналы:

Менталист Николоз Цаава:

Отель:

Международная конференция “Управление автопарком 2016”

15 – 16 сентября 2016

Отель Яхонты, Подмосковье

Выступления:

1. Мария Шарапова, руководитель отдела по административным услугам и корпоративному транспорту Johnson & Johnson

Построение транспортной политики компании

2. Константин Бнатов, управляющий автомобильным парком Pfizer

Денежная компенсация “Car Allowance”. Опыт внедрения.

3. Анна Гудкова, операционный директор ДТПнет

Корпоративные водители: 10 ночных кошмаров начальника автопарка

4. Валерий Дердюк, менеджер по управлению автопарком Danone

Управление штрафами. Решение проблем со сбором данных по штрафам и оплатой

5. Татьяна Арабаджи, директор Russian Automotive Market Research

Анализы и тенденции рынка корпоративных закупок автомобилей

6. Наталья Живкович, руководитель корпоративного отдела Авиньон

Хороший выбор. Что важнее выгода или стратегия.

7. Виктория Тот, главный редактор журнала “Административный директор”

Смена операционной модели владения автопарком как способ оптимизации затрат.

8. Алексей Ширяев, менеджер по транспорту и безопасности по стране Coca-Cola HBC Россия

Оптимальный портфель лизинговых компаний – критерии выбора партнера лизингополучателем

9. Денис Степанов, директор по операционному лизингу ВТБ Лизинг

Формула успешного тендера по операционному лизингу

Промо:

Международная конференция “Закупки и снабжение в нефтегазовом секторе”

18 – 19 февраля 2016

Марриотт Москва Гранд Отель, РФ, Москва, Тверская, 26/1

Данная международная конференция знакомит участников с наиболее актуальными практиками и вариантами решения текущих проблем, а также анализирует тенденции на рынке в области организации работы отдела закупок, ценообразования, локализации производства, управления запасами. Ведущие практики и эксперты в данной области представляют лучшие примеры эффективной организации отделов закупок и снабжения, новые стратегии по закупке материально-технических ресурсов и нематериальных сервисов, а также различные варианты оптимизации затрат. Компании-интеграторы рассказывают о наиболее оптимальных платформах для автоматизации процессов закупочной деятельности, для создания более прозрачной системы, а также для быстрой оптимизации расходов на функционирование отделов закупок и снабжения.

Выступления:

1. Михаил Шуляк, начальник управления поставок НОВАТЭК

Организация закупочной деятельности в условиях падения цен на нефть

2. Лилия Каримова, директор по закупкам и логистике Air Liquide

Эффективная модель организации закупок

3. Павел Майор, директор по продажам БТК групп

Сергей Слепов, руководитель направления по работе БТК групп

Решение задачи импортозамещения в комплексных поставках спецодежды, обуви и СИЗ для работников нефтегазовой отрасли

4. Сергей Моштаков, старший бизнес-консультант BearingPoint

Имитационное моделирование в цепях поставок: от идеи до эффекта

5. Лейсана Хабибуллина, руководитель Торгово-закупочной площадки Татнефть

Электронные торги в системе Торгово-закупочной площадки Татнефть

6. Александр Геллер, исполнительный директор, Электронная торговая площадка ETPRF.RU

Электронная торговая площадка как элемент в работе организации

7. Олег Аралов, начальник управления аккредитации основных видов продукции НИИ Транснефть

Система управления качеством продукции, закупаемой ОАО «АК «Транснефть»

8. Андрей Мороков, специалист отдела обеспечения производства РУП Белоруснефть

Механизмы проведения диагностики системы закупок и снабжения

9. Дмитрий Бражников, партнер РТФ

Доращивание и формирование базы поставщиков малых и средних технологических компаний для целей организаторов закупок

10. Александр Казанский, директор департамента организации тендерных процедур Башнефть

Автоматизация закупочной деятельности

11. Сергей Солотнов, руководитель направления электронных закупок Газпром нефть

Внедрение систем электронного документооборота (СЭД)

12. Сергей Дашков, руководитель рабочей группы Национальной ассоциации институтов закупок

Генеральный директор Энергосервис

Риски заказчика при оценка заявок участников закупочных процедур, проходящих по нормам Закона 223-ФЗ. Привлечение стороннего Организатора закупок

13. Александр Бурков, эксперт Института управления закупками и продажами им. А.Б. Соловьева НИУ ВШЭ

Проблемные аспекты взаимодействия заказчика и поставщика при проведении закупок

14. Александр Аржанкин, заместитель начальника отдела закупок и логистики Air Liquide

Принцип TCO проекта на примере закупки технических газов в баллонах

15. Павел Горячев, заместитель директора департамента МТО Группы ERIELL

Учет запасов и управление запасами

16. Алина Засимович, директор практики консультационных услуг EY

Построение Системы мониторинга для снижения материальных потерь в основных и вспомогательных процессах

17. Алексей Кравцов, председатель Арбитражного третейского суда города Москвы

Споры по договорам поставки – опыт коммерческого арбитража

18. Владимир Савченко, начальник отдела государственных закупок Департамента конкурентной политики и политики в области государственных закупок Евразийской экономической комиссии

Реализация процессов импортозамещения в ЕАЭС

Журналы:

Season 3. Arabia

2015

Interesting and rare moments of everyday life of people in the Middle East.

City Insight

Israel: Jerusalem, Nazareth, Netanya, Tel Aviv

Turkey: Ankara, Dalyan, Ephesus, Istanbul, Marmaris

United Arab Emirates: Abu Dhabi, Dubai, Sharjah

Place Insight

Heritage: Hatshepsut’s Temple, Karnak, Petra, Pyramids

Wildlife: Dead Sea, Jordan River, Pamukkale

Season 1. Bonus.

City Insight

Belarus: Buynichi

Russia: Arkhangelskoye

Event Insight

Military: V-Day Parade 2015

Stats: Countries 5 (30), Cities 20 (81), Events 1 (14), Places 7 (15)

Celebrating 100 Posts!!!

Anniversary Stat:

and

New York Institute of Finance

via Edx.org Platform

13.11.2015

Online Educational Course “Understanding the Federal Reserve “

The course is about the structure and purpose of the Federal Reserve and how its actions impact not just the US economy, and financial institutions, but individual investors and savers alike.

By the end of this course, you will:

The Chartered Institute of Procurement & Supply (www.cips.org)

Certificate in Procurement and Supply Operations

The CIPS Certificate in Procurement and Supply Operations is a vocationally related qualification. It has been accredited by the Office of Qualifications and Examinations Regulator (Ofqual) in the UK and appears on the Register of Regulated Qualifications. Please refer to register.ofqual.gov.uk

Procurement and Supply Principles

Learning Outcomes

1.0 Know the roles of procurement and supply within organisations

1.1 Define the common terms that describe aspects of procurement and supply

1.2 Describe the roles of procurement and supply in organisations

1.3 Describe the benefits of effective procurement for organisations

1.4 Identify the five rights of procurement and supply

2.0 Know how products and services are received from suppliers and delivered to customers

2.1 Describe the delivery of products and services that organisations make to customers

2.2 Describe the delivery of products and services made by external suppliers

3.0 Know the main stages of the sourcing process

3.1 Describe the main stages of a sourcing process

4.0 Understand what makes up the main components of a supply chain

4.1 Explain the main components of a supply chain

Procurement and supply functions

Procurement and supply functions

Learning Outcomes

1.0 Know the main types of organisations and how they operate

1.1 Identify the main types of organisations

1.2 Describe how organisations operate

1.3 Identify the main operating functions with in organisations

2.0 Know the main elements of a procurement and supply function

2.1 Describe the use of mission and vision statements and objectives by a procurement and supply function

2.2 Describe the main roles and structures of a procurement and supply function within an organisation

2.3 Define the main procedures that can be created by a procurement and supply function

3.0 Know the main market factors that impact on a procurement and supply function

3.1 Identify the main economic sectors that impact on a procurement and supply function

3.2 Describe the impact of demand and supply on markets

3.3 Describe how market factors impact on the procurement and supply activities of an organisation

Procurement and supply processes

Procurement and supply processes

Learning Outcomes

1.0 Know the main components of contractual agreements

1.1 Describe the main types of contracts

1.2 Identify the main kinds of pricing arrangements applied in commercial contracts

1.3 Describe the different documents that compose a contract for the purchase or supply of goods or services

2.0 Know the main sources of information on suppliers and customers

2.1 Describe the use of the Internet to locate details about suppliers and customers

2.2 Describe the use of credit rating agencies

2.3 Describe the use of intranet, extranet and internet sites to publicise information

3.0 Know the main types of systems for supplier selection, ordering and payment

3.1 Describe the use of electronic sourcing systems for supplier selection

3.2 Identify systems used in procurement and supply

3.3 Describe P2P (purchase to pay) systems for ordering from suppliers and payment to suppliers

Procurement and supply administration

Procurement and supply administration

Learning Outcomes

1.0 Understand the need for the effective and efficient administration of purchases made with external suppliers

1.1 Define effective and efficient administration

1.2 Explain the administration of the pre contract stages of a sourcing process

1.3 Explain the administration of the award and post award stages of a sourcing process

1.4 Describe the need for approvals in the administration of procurement and supply

2.0 Know the main techniques used for ordering supplies

2.1 Describe what is meant by direct and indirect supplies

2.2 Identify the main costs associated with holding inventories

2.3 Describe techniques commonly used for ordering inventories

3.0 Know the main approachesto achieving timely deliveries of products or services

3.1 Define the processes that should be used when expediting supplies

3.2 Describe the importance of effective communication with suppliers and customers to achieve timely deliveries

3.3 Describe the use of forecasting to achieve timely deliveries of supplies

Procurement and supply stakeholders

Procurement and supply stakeholders

Learning Outcomes

1.0 Know the main stakeholders in procurement and supply

1.1 Identify the main external stakeholders in procurement and supply

1.2 Identify the main internal stakeholders that can be involved in purchases from suppliers and supplies delivered to customers

2.0 Know the main approaches for conflict resolution with stakeholders in procurement and supply

2.1 Describe how conflict can arise in the work of procurement and supply

2.2 Describe approaches to conflict resolution with stakeholders in procurement and supply

2.3 Explain the contribution that effective teamwork can make when dealing with conflict with stakeholders in procurement and supply

3.0 Know why quality management is important in procurement and supply

3.1 Define the main components of quality management in procurement and supply

3.2 Identify the costs of quality

3.3 Describe the main techniques associated with quality assurance and quality management

4.0 Know why clear ethical codes of practice should be used in procurement and supply

4.1 Describe the role of ethical codes in procurement and supply

4.2 Describe the details that should be included within standard ethical codes

4.3 Describe the impact of corporate governance on a procurement and supply function

Exam Letter

Exam Results

Exam Results Letter

Certificate

MBA Boutique Event MBA25

26.09.2015

Moscow, Russia, Swissotel Krasnye Holmy, Kosmodamianskaya nab., 52 bld. 6

MBA25 is the unique MBA Boutique Event connecting best world business schools with high-caliber candidates. Only TOP schools. Only TOP candidates.

Program:

Application workshop